August 4, 2020

The COVID-19 pandemic ushered in a grim reality that hospitals all over the globe may not have sufficient numbers of ventilators to care for the onslaught of critically ill patients. Moreover, manufacturers were not expected to be able to meet the demand for traditional ventilators in the timely manner required to save lives.

In response to this global health crisis, the Defense Health Agency in the Department of Defense, created the “Vulcan Innovator Challenge” to develop easily manufactured, low cost ventilators. Over the course of seven days, 172 innovative ideas were submitted by industry, universities, government agencies, and individuals, all with the singular focus to design a ventilator to fill the impending gap in capacity and save lives.

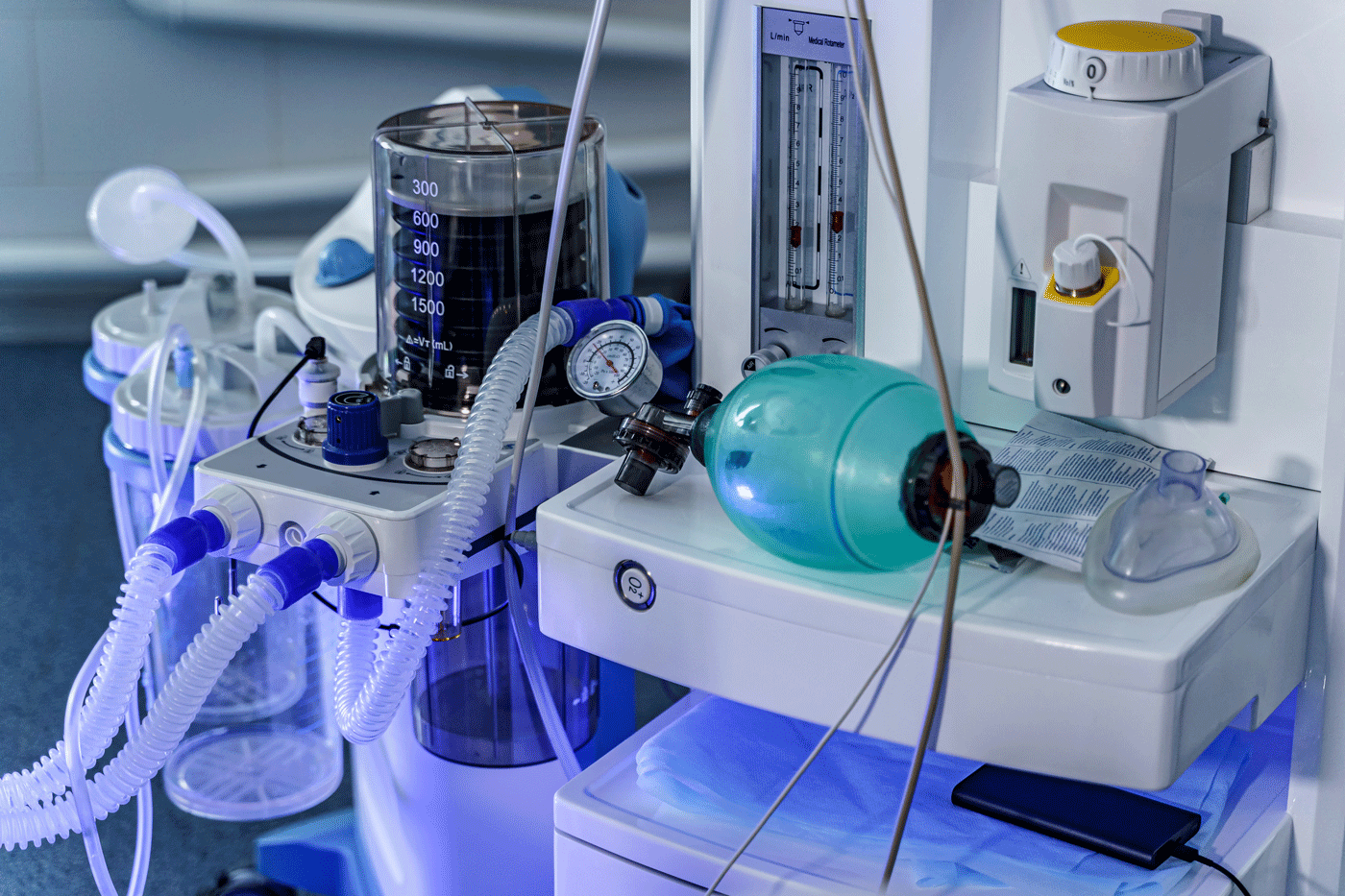

Two panels of experts in the fields of engineering and critical care anesthesiology, medicine, and surgery selected five of the most promising designs for further evaluation. Following selection and prototype development, we aimed to evaluate the frontrunning limited performance ventilators in an in vivo system, including a clinically relevant model of acute respiratory distress syndrome.

The Uniformed Services University of the Health Sciences, including its Department of Anesthesiology and the Defense and Veterans Center for Integrative Pain Management, with the support of HJF and the Department of Defense Joint Acquisition Task Force, provided opportunity for five prototypes selected by the Vulcan Innovator Challenge to be evaluated in a large animal lab. The testing consisted of four parts. Parts one and two evaluated, selected and measured ventilator parameters in a mechanical test lung and in healthy 70-100 kg swine, respectively. The ventilator parameters evaluated included positive end-expiratory pressure, peak inspiratory pressure, tidal volume, respiratory rate, and fraction of inspired oxygen. Part three evaluated the ventilator’s ability to adjust minute ventilation to control hyper or hypoventilation in a healthy animal. Part four evaluated the ventilator’s ability to maintain adequate controlled ventilation in a 70-100 kg swine with induced acute respiratory distress syndrome.

In response to the global crisis, many well-intentioned innovators developed new designs or fabricated ventilators out of other devices. The media and general public celebrated the innovations as solutions to fill the gap, yet it also revealed how difficult it is to develop safe, low cost, easily manufactured ventilators. Preliminary results revealed several design flaws in the prototypes, which required refinement of the devices. While the prototypes developed and evaluated through the Vulcan Innovator Challenge may be viable last-resort alternatives in severely resource-strained environments, rigorous monitoring and well-trained operators are even more important than with conventional ventilators.